In the intricate realm of manufacturing, where meticulous design and precision execution are paramount, injection molding emerges as an exemplary technique that has reshaped the landscape of plastic component production. This intricate process seamlessly converts molten polymers into intricately designed shapes, unleashing a torrent of possibilities that span industries. Join us on an in-depth exploration of the multifaceted world of injection molding, unraveling its key technical facets, advantages, and the vast horizons it unlocks.

The Intricacies of Injection Molding

Injecting life into a concept through injection molding is a symphony of science and engineering, where every note resonates with precision. It starts with an intricately designed mold and culminates in the fabrication of intricate plastic components. This harmonious process melds advanced machinery, polymer materials, and cutting-edge design principles to sculpt an array of products that shape our modern world.

1. Design and Prototyping: Engineering the Blueprint

The overture commences with meticulous design. Engineers craft intricate 3D digital models, capturing every minutiae of the intended product. These models dictate not only the form but also factor in elements such as material selection, wall thickness, and gate placement. Prototyping refines these designs, serving as a proving ground for the virtual blueprint.

2. Mold Fabrication: Sculpting Reality from Concept

The next act unfolds in the realm of mold fabrication. Masterful toolmakers meticulously fashion molds, often employing high-strength materials such as hardened steel or aluminum. These molds are works of engineering art, embodying the intricacies of the final product's geometry. Mold design balances factors like optimal material flow, efficient cooling, and seamless ejection.

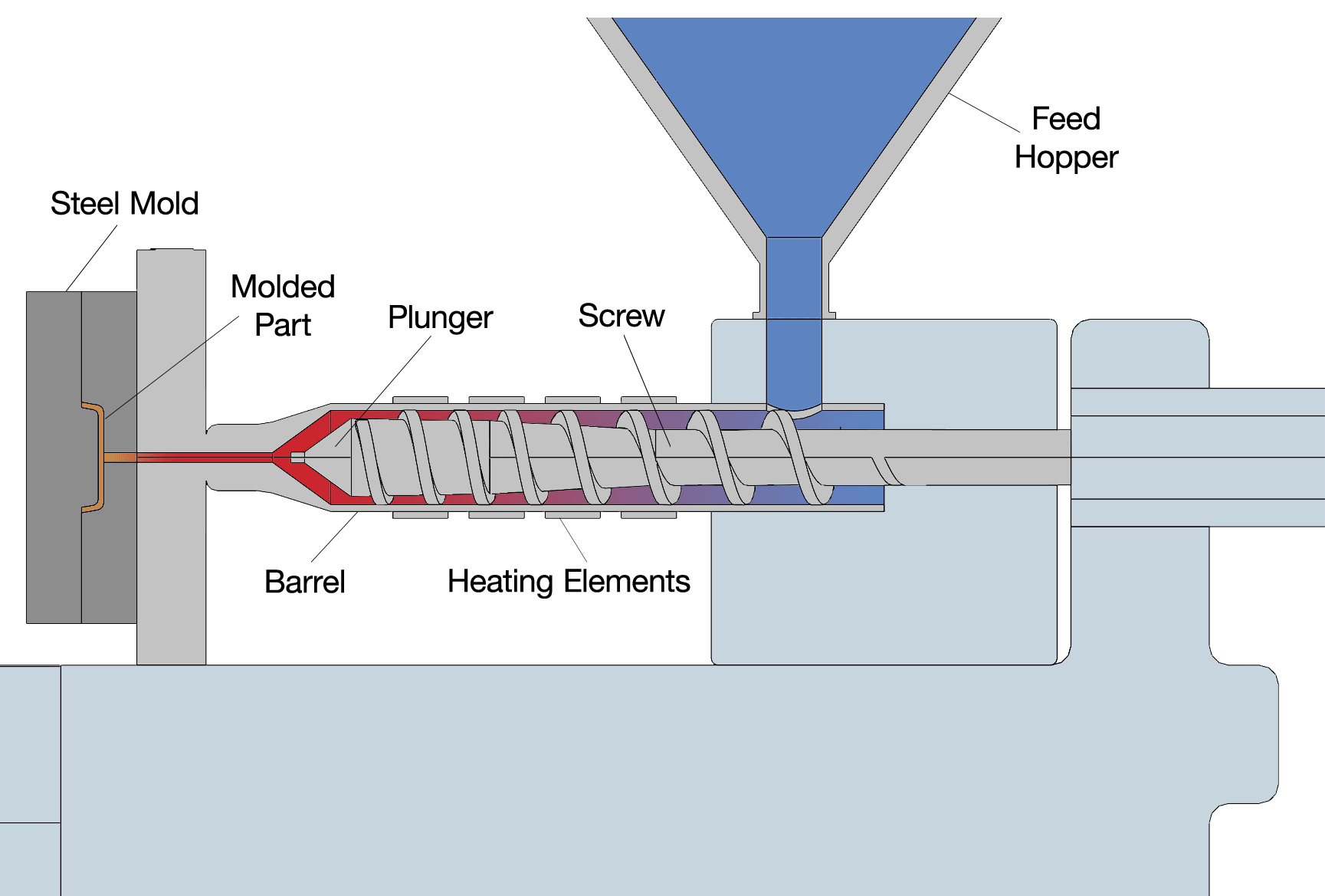

3. Injection: Thermal and Hydraulic Ballet

As the curtain rises on the injection stage, polymers take center stage. Polymer pellets are thermally transformed into a molten state and injected into the mold at high pressures. The material meticulously traverses the labyrinthine channels of the mold, imprinting its form upon every intricate recess. Upon cooling and solidification, the mold is unsealed, revealing the nascent component within.

4. Cooling and Ejection: Calculated Quenching

Cooling orchestrates a crucial act in this process. Meticulous temperature control dictates the solidification pace of the polymer. Perfecting this stage optimizes material properties and minimizes cycle times. As the part achieves structural integrity, the mold opens, and intricate ejection mechanisms delicately coax the component out, necessitating precision to avoid distortion or imperfections.

5. Post-Processing: Precision Refinement

The freshly minted components often require meticulous post-processing. Trimming excess material, eliminating gate vestiges, and bestowing final finishing touches assume significance. This stage guarantees not just visual appeal, but adherence to exact specifications and performance benchmarks.

Advantages and Avenues: The Technological Leverage

Injection molding boasts an array of advantages that underscore its dominion in modern manufacturing. Its efficiency shines through high-volume production with unparalleled consistency. The process's versatility spans industries, encapsulating a vast spectrum from consumer goods to intricate medical devices, from automotive components to intricate electronics.

A World of Boundless Creativity: Engineering Artistry

In the hands of adept engineers, injection molding kindles the fire of creativity. Intricate geometries, fine details, and bespoke designs come alive with astounding accuracy. Be it precision medical instruments that revolutionize healthcare or consumer gadgets that redefine convenience, injection molding weaves its technical tapestry across every facet of contemporary existence.

Conclusion: The Fusion of Art and Engineering

Injection molding is more than a process; it's the embodiment of art intertwined with engineering precision. From initial design inception to the final realized component, every step demands technical expertise, unswerving attention, and an unwavering commitment to perfection. In a world witnessing the dawn of products that define our era, injection molding is the ultimate testament to the seamless synthesis of innovation and technology in the realm of manufacturing.