In the intricate tapestry of the steel industry, one unassuming yet absolutely critical element reigns supreme: sheet metal. This unyielding yet versatile form of steel, characterized by its flatness and pliability, serves as the bedrock for an array of applications across industries. Join us as we delve into the technical intricacies of sheet metal, unveiling its profound significance, fabrication methodologies, and its far-reaching impact on the steel sector.

Sheet Metal Composition: Precision in Thinness and Strength

Sheet metal, characterized by its low thickness relative to its width, is the embodiment of steel's exceptional properties. Its strength-to-weight ratio and ductility render it an engineering marvel, making it ideal for applications requiring both structural integrity and maneuverability.

Fabrication Techniques: Forging Beauty from Steel

Sheet metal's journey from raw material to refined product involves an array of intricate fabrication techniques. Two paramount methods in the process are cutting and forming.

1. Cutting Techniques:

Shearing: Employing robust blades, shearing precisely cleaves through sheet metal to yield straight-edged cuts. This method is optimal for geometric simplicity and dimensional accuracy.

Laser Cutting: Harnessing the energy of a high-powered laser, this technique vaporizes metal to create intricate contours with minimal heat-affected zones. Its precision is particularly beneficial in intricate designs.

2. Forming Techniques:

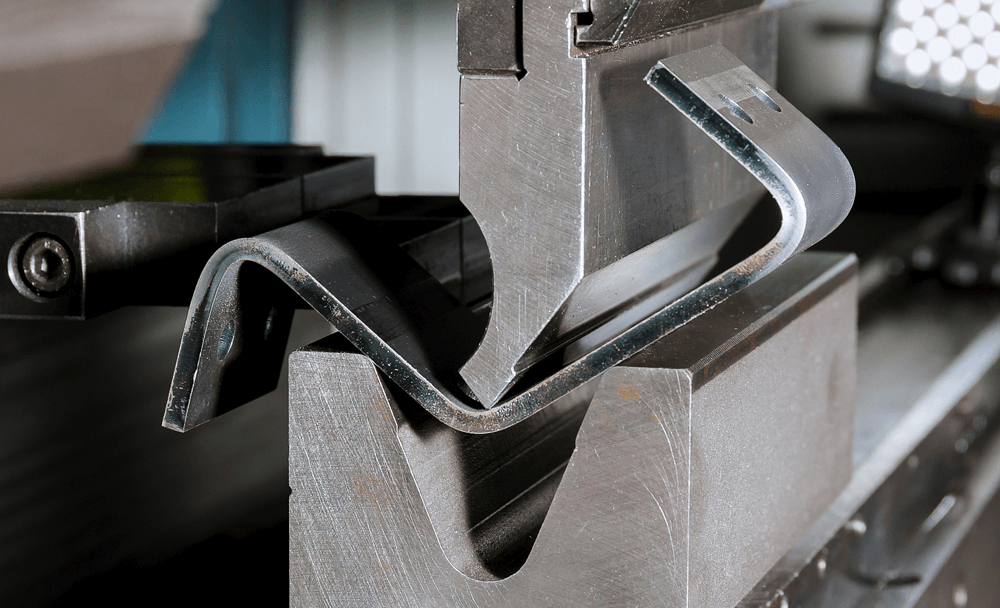

Bending: Leveraging hydraulic or mechanical press brakes, sheet metal is precisely bent to achieve desired shapes and angles. This process introduces structural integrity and aesthetic refinement.

Deep Drawing: By applying controlled force to a sheet metal blank, deep drawing coaxes it into intricate forms such as cups or cylindrical shapes while maintaining material thickness consistency.

Diverse Applications Fueling Steel Industry Growth

Sheet metal's pivotal role within the steel industry extends across a myriad of sectors:

1. Construction and Architecture: From roofing and cladding to elaborate façades, sheet metal shapes the modern urban landscape, offering both durability and aesthetic allure.

2. Automotive Sector: Sheet metal forms the backbone of vehicles, composing critical components like body panels, chassis parts, and structural reinforcements, ensuring both safety and efficiency.

3. Appliance Manufacture: Common household appliances, ranging from refrigerators to stoves, harness sheet metal's robustness to ensure long-lasting functionality.

4. Machinery and Industrial Equipment: In the realm of industrial machinery, sheet metal components provide stability and precision, translating into seamless mechanical operation.

5. Electronics and Enclosures: Within the electronics domain, sheet metal enclosures provide a protective cocoon for intricate electronic components, affording secure housing and effective heat dissipation.

Economic Efficiency and Environmental Sustainability

The economic resonance of sheet metal reverberates across industries. Its unparalleled versatility streamlines production processes, slashing lead times, and amplifying overall productivity. The judicious utilization of precise fabrication techniques like laser cutting minimizes material wastage, yielding economic efficiency.

Furthermore, sheet metal embodies the principles of ecological sustainability. Steel's inherent recyclability without compromising quality forms the cornerstone of a circular economy, where sheet metal products can be perpetually repurposed, epitomizing resource conservation.

Conclusion: A Backbone of Technological Progress

Sheet metal within the steel industry is akin to the intricate lattice within a skyscraper's framework - strong, agile, and foundational. Its metamorphosis through cutting and forming techniques is the crucible of modern innovation, shaping objects of utility and aesthetics. As industries perpetually evolve and innovate, sheet metal stands steadfast, etching steel's resilience into the blueprint of technological advancement, engineering excellence, and architectural innovation.